The launch of ISCAR’s HELIMILL in the 1990s marked a pivotal innovation in the world of milling tools, especially with its helical cutting-edge design featuring parallelogram-shaped carbide inserts. The HELIMILL’s unique structure revolutionized milling with its consistent rake and relief angles, a helical edge, and a design that minimizes cutting force variations while enhancing durability. These features improved cutting accuracy and stability, elevating milling capabilities significantly.

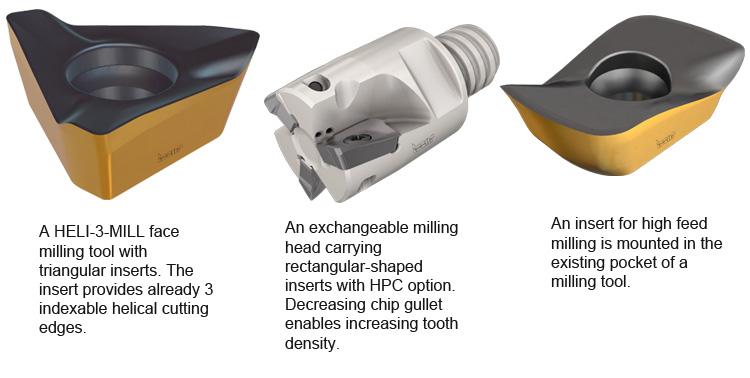

Over time, continuous improvements transformed the HELIMILL’s classical insert design. The parallelogram insert evolved with more aggressive cutting-edge angles and advanced carbide grades, creating robust tools fit for the demands of modern machining. However, one limitation remained: the parallelogram’s two cutting edges. ISCAR addressed this with a new, triangular insert concept that delivers three cutting edges while maintaining the durability and accuracy of the helical design. This triangular shape allowed for a larger central bore, enabling stronger clamping with larger screws and enhanced tool security, especially in applications requiring high torque and precision.

The HELI-3-MILL series, ISCAR’s next-generation milling solution, adopts these triangular inserts, offering greater durability and better ramp-down capabilities. Nevertheless, the original parallelogram shape still holds advantages, particularly in smaller tool diameters and high-feed milling applications. Its narrow width strengthens the tool body, especially crucial for cutters with extended flutes, enhancing both rigidity and performance.

ISCAR’s 90-degree indexable milling cutter series now combines both triangular and parallelogram-shaped inserts, optimizing flexibility for a range of industrial applications. The parallelogram insert continues to play a vital role, especially in machining high-temperature superalloys, titanium, and tough stainless steels, where effective cooling is essential. ISCAR’s HELI2000 family, an evolved form of HELIMILL, introduces tools featuring high-pressure cooling (HPC) to reduce heat at the cutting edge, increasing cutting speed and efficiency while facilitating smaller chip gullets and higher tooth densities.

ISCAR has also enhanced its HELIMILL platform with new carbide grades like IC5600 for steel and IC716 for titanium, along with inserts designed for high-feed and high-hardness applications. The expansion of the HELIALU family for aluminum alloys and the integration with ISCAR’s modular MULTI-MASTER and FLEXFIT systems further add to the platform’s versatility. With this approach, ISCAR’s HELIMILL series continues to set new standards in milling, offering precision, adaptability, and reliability to meet the demands of modern manufacturing.

For more information : www.iscar.in